This is where cost drivers come in. Every cost in your business model can be correlated to one of five main cost-drivers, or factors that determine how much the cost is. Employee headcount. Certain costs have a lot to do with how many employees you have, and how they will increase or decrease over time based on your headcount.

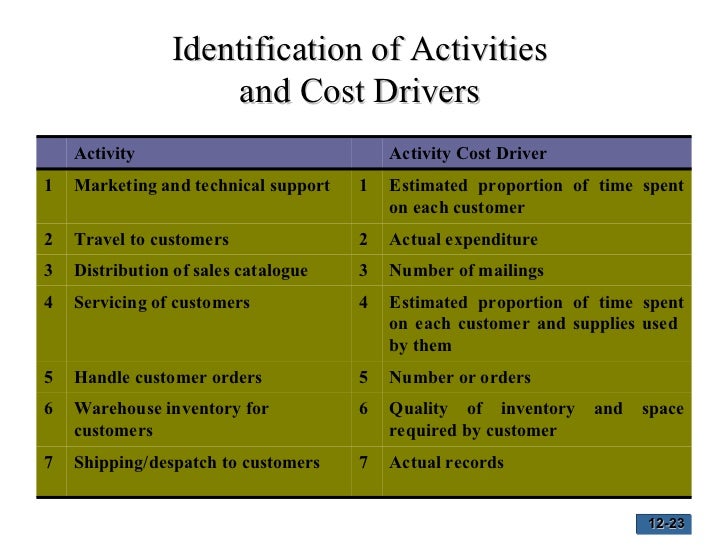

A cost driver: • Is any factor whose change causes a change in the total cost of a related cost object. Hence a change in the level of cost driver will cause a change in the level of the total cost of a related cost object. Examples of cost driver used in the following business units: • Research & Development:- Number of research projects, technical complexities of the projects • Design of products, services & process:- number of products in design, number of parts per product, • Marketing:- number of advertisement run, number of sales personnel, sales revenue • Distribution:-number of items distributed, number of customers, weight of items distributed • Customer services:-numbers of service calls, hours spent in servicing of products. Rukovodstvo po remontu i ekspluatacii avtobusa yutong 6737d.

Windows 7 64-bit iso. The textbook answer defines cost drivers as those factors that determine the overall cost of. As an example, in manufacturing the cost drivers may be processing time or number of steps to produce the product.

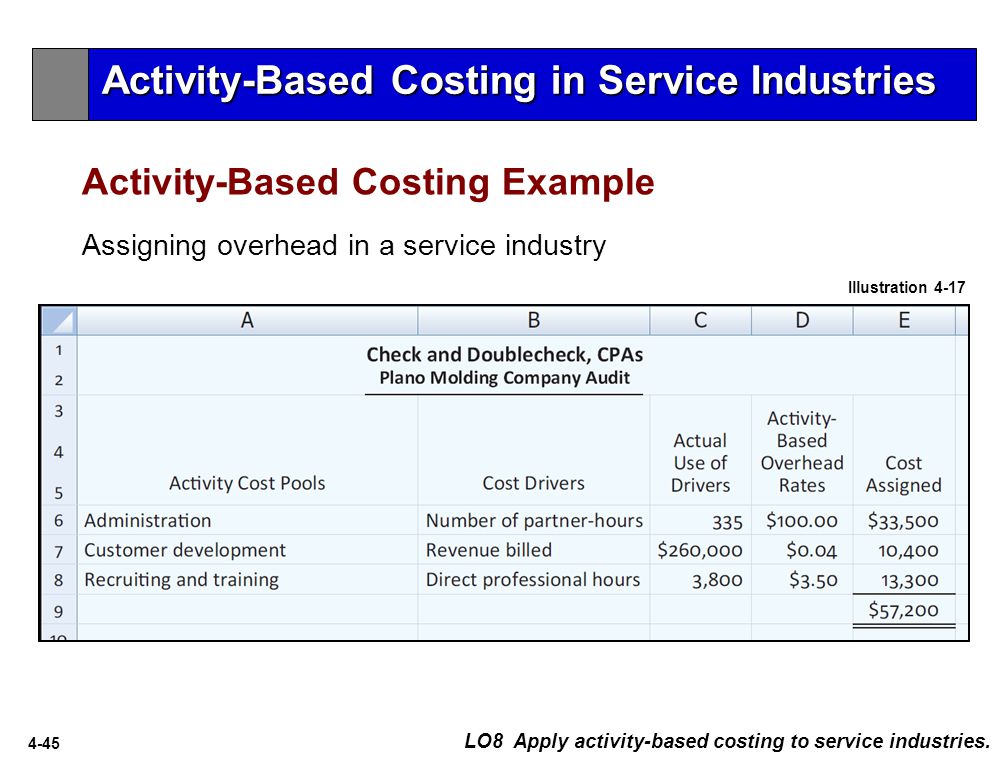

In service, the cost drivers could be the actual ratio of billable to non-billable time. Or it may simply be the actual compensation package cost for labor. The key is that this cost driver is used to allocate the general overhead and administration costs through Activity Based Costing (ABC Costing). But this article isn’t about the textbook answer; it’s about understanding what drives costs in the small business world. Sometimes it ends up being the textbook answer, but most often it is some common denominator with the company that prohibits greater profits. I’ll give you a simple real life example. Ray’s Auto Repair Back in the 90’s I had a client named Ray.

His wife ran the office of the auto repair shop. He had four bays and four mechanics and was open five days a week. At the end of each month they barely made enough money to survive.

So he asked me why he’s not making more money. His labor rate matched the competition and he had plenty of work. After several years of going there and interacting with him and his wife it really wasn’t hard to figure out. Sometimes the obvious is ignored. First, he didn’t have enough bays to process the volume of work necessary to generate enough gross profit to cover his general operating costs. Why do you think Firestone and Goodyear facilities have no less than 10 bays?

In addition they are open seven days a week. A common discussion issue with my visits related to the inability of the mechanics to get the work done quickly. It was always the same issue, lack of experience or training.

Recent Pages

- Serial Number Garritan Personal Orchestra 5 Torrent

- Aquasoft Slideshow Ultimate 9 Serial Number

- Browning 1900 Serial Numbers

- On Connait La Chanson Torrent 411 Ai

- Protek 6510 Oscilloscope Service Manual

- Bmw Update Dvd Road Map Europe Professional 2014 Download

- Virtual Drive 701 Free Download

- Naruto Gekitou Ninja Taisen Special Wii Iso Download Kitatikuu77